IMSPost 8.3n Suite

IMSPost 8.3n Suite

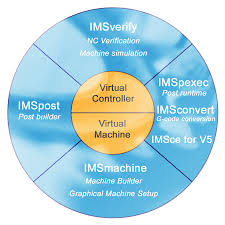

IMSPost is a professional software to convert the file location cutting machine CAD / CAM (CL) into machine code (G / M) specific according to the requirements of the NC. With a library, the flexibility of the processor as standard and the machine configuration, you can start to create the file NC immediately. User interface IMSpost intuitive (have checklist and Windows GUI) provides the working environment efficient, smooth operation with all the CAD / CAM system and the hardware platform itself. Processor macro IMS, with level debugger source, provide support for the configuration post-processing the most complex.

IMSPost - conversion Support files for CAM

Integrated APT / CL, G code, and view mode machine provide the complete picture to develop this CNC. CNC controller the virtual IMSpost provides complete analysis on machine code and provide a true picture of the motion of the tool. Virtual controller provides support for the control, NC from all the major manufacturers.

The features of IMSPost

- High speed machining

- Auto data switch point-to-point format NURBS

- Interface or menu by the user to customize (call DLL, script or your own program in the implementation process post-processing)

- Mounting ring provides point data-points in any plane whatsoever

- File CL read before

- Linear chemical enhancement for multi-axis

- Optimized output using the tangent linear

- Advanced technology, using C ++ and Windows GUI

- Supports all classes of machines with any number of linear axes or rotation axes

- Cycle drilling 5 axis

- Automatic support for the coaxial line

- Cycle or canned cycle drilling simulator for the machine does not have support cycle

- Use the same processor for any CAM system or hardware platform does

- Debugging tool the macro language and the source easy to use keep track of each output line and each command

- Access to all the variables double handle internal and source code

- Support type output conversation

- Syntax post-processing user-defined

- Integrated control simulation / technology post reverse

- Safe Software FME Desktop 2019.0.2.19260

The ETL tool space flexible and strong helps you to easily translate, transform and integrate data

The ETL tool space flexible and strong helps you to easily translate, transform and integrate data - Rank Tracker Enterprise 8.38.11

Analysis software to check keyword ranking of your website on Google, Bing and Yahoo.

Analysis software to check keyword ranking of your website on Google, Bing and Yahoo. - PHP Report Maker 12.0.7

Software powerful reporting can automatically access the Web reports from the database differ in format PHP

Software powerful reporting can automatically access the Web reports from the database differ in format PHP - Meteonorm 8.2.0

A unique software to create meteorological data for different climate and geography regions in the world of the world.

A unique software to create meteorological data for different climate and geography regions in the world of the world. - Korf Hydraulics 3.5

A software application to calculate the flow rate and pressure in pipes and pipe networks

A software application to calculate the flow rate and pressure in pipes and pipe networks - FRSProductMgr 4.0.12

Software business management such as inventory management, tracking of customer sales, management of products on the website

Software business management such as inventory management, tracking of customer sales, management of products on the website - ClickCharts Pro 9.57

The software creates mapping intuitive representation of a process, visual organization, and science

The software creates mapping intuitive representation of a process, visual organization, and science - Classroom Spy Professional 5.5.2

Management software effective classroom. Manage and track activities of all the computers of students in the school

Management software effective classroom. Manage and track activities of all the computers of students in the school - BarCode Reader 11.2.0.1987

A reliable app to give you a quick way to scan barcodes on your computer

A reliable app to give you a quick way to scan barcodes on your computer - Arclab Dir2HTML 4.1

Software convert only the HTML, build the file index html out of the folder structure and files on your computer

Software convert only the HTML, build the file index html out of the folder structure and files on your computer